Technology ServoDisk Motors

Comparison Servodisk / standard ironcore motor

Ironcore Motor

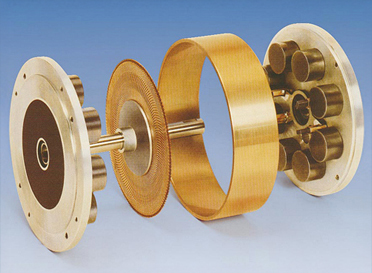

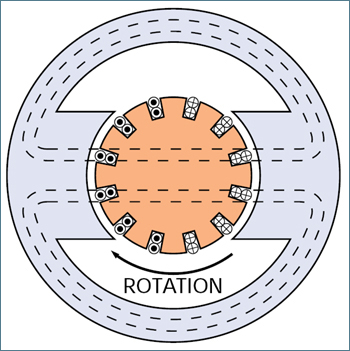

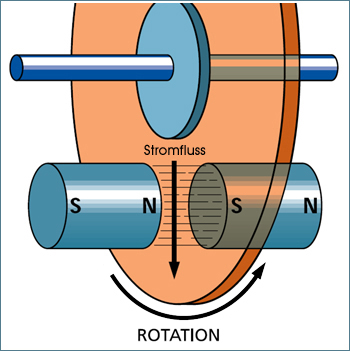

A conventional ironcore motor uses a radial design with magnets placed concentrically around the shaft in such a way as to produce a radial magnetic field. The armature consists of slotted steel laminations wound with coils of wire which interact with the magnetic field to produce torque. As the motor rotates a commutator automatically maintains the correct current flow. A ServoDisk motor uses entirely different physical construction. The motor is designed with the magnetic field aligned axially, parallel to the shaft.(see image Servodisk Motor).

Servodisk Motor

The conductors in the armature have a current flow which is perpendicular to the magnetic field (radial to the shaft). This produces a torque perpendicular to both the magnetic field and the current (the left-hand rule). This force rotates the shaft. This construction approach is much more efficient than the radial design of conventional ironcore motors and eliminates the heavy iron armature and the electrical losses associated with it. The large number of commutations possible with the unique flat armature produce considerably smoother torque output.

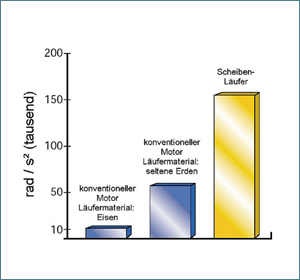

High acceleration

The thin, low-inertia armature design leads to exceptional torque-to-inertia ratios. This translates into blazing acceleration (Fig. 4). A typical ServoDisk motor can accelerate from 0 to 3000 rpm in only 60 degrees of rotation. In some applications, the entire move can be performed in less than 10 milliseconds.

This means shorter cycle times, more moves per second and higher throughput. For incremental motion applications, this translates into higher productivity and more profitability.

Perfectly smooth rotation

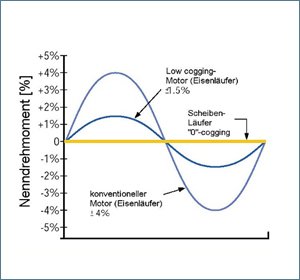

If you rotate a conventional motor when it is unpowered, you will notice that it pulls into certain preferred positions.

This occurs when the iron laminations in the armature line up with the permanent magnets on the stator. This phenomenon is called “cogging.” It also occurs when the motor is powered and shows up as torque disturbances which can be a serious problem in critical applications. The ServoDisk armature, being ironless, is not attracted by the magnets and. consequently, has intrinsically zero cogging. The result is ultra-smooth rotation at any speed.

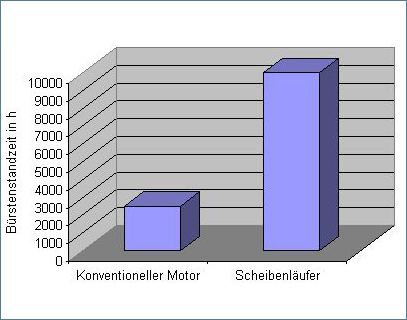

Long operation life

Because there is no iron, there is nearly no inductance. The result is no arcing, because there is no stored energy in the armature to be dissipated during commutation. In an ironcore motor. a lot of energy is stored in the magnetic field of each coil. When this field collapses, the energy may be discharged by arcing to the brushes. Arcing, not friction, is the major cause of brush wear. The elimination of arcing leads to very long brush life in most applications. In fact, depending on the application, it is possible for the brushes to last as long as the bearings.

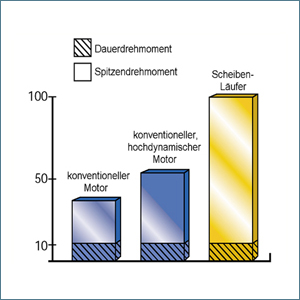

High peak torque

For rapid acceleration and deceleration, higher than normal torque is usually required. To produce this temporary peak torque, a peak current is applied to the motor. In an iron-core design, the magnetic field of the armature can interact with and demagnetize the permanent magnets. Because of this effect, peak current is generally limited to 2 or 3 times the continuous current rating. With the non-magnetic ServoDisk armature and axial magnetic field, this problem is virtually eliminated. Most ServoDisk motors are rated for peak current of 10 times the continuous rating.

Compact size

The disc armature design leads to a unique flat motor package.

This is generally easier to design in than much longer conventional motors. These key factors can optimize your mechanical design.